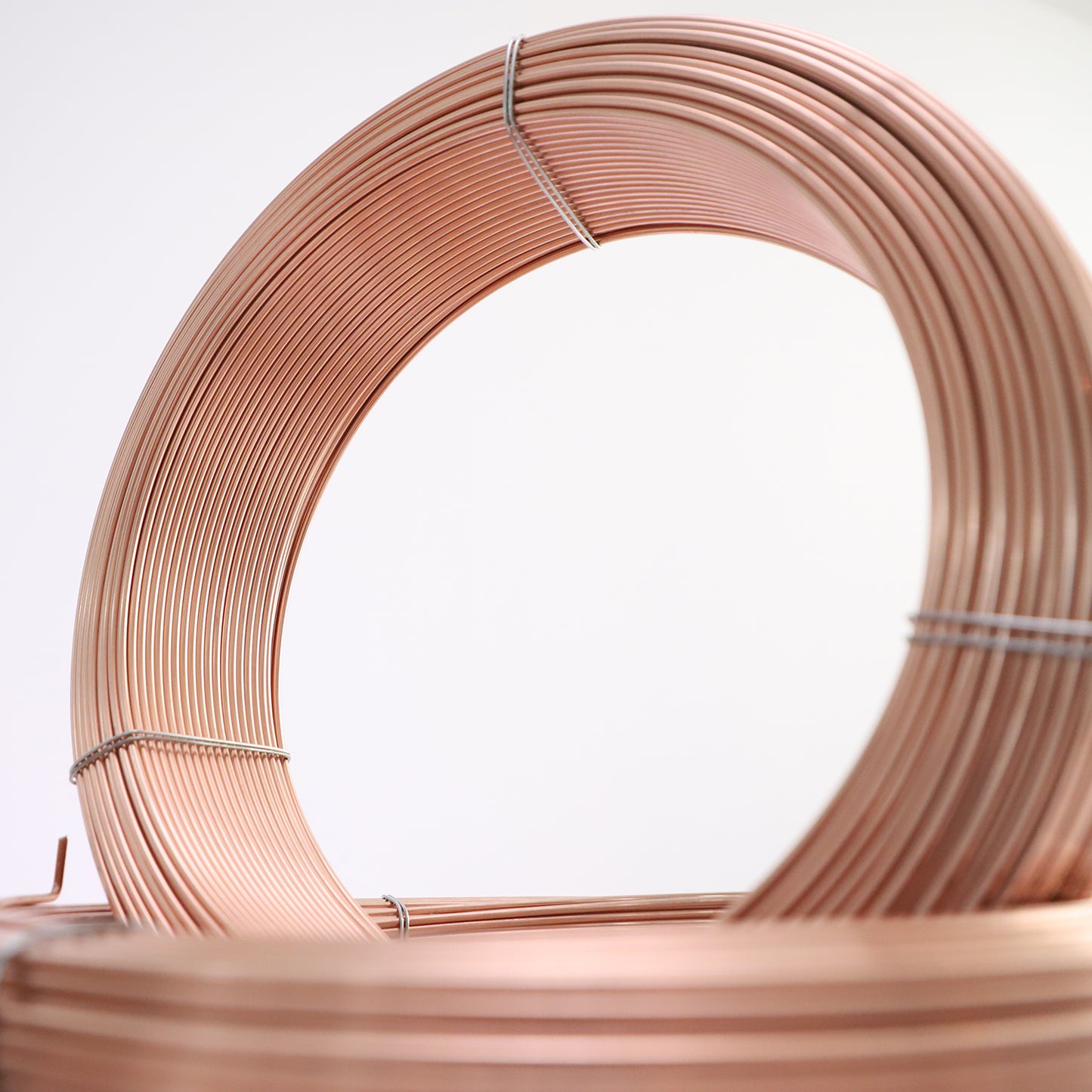

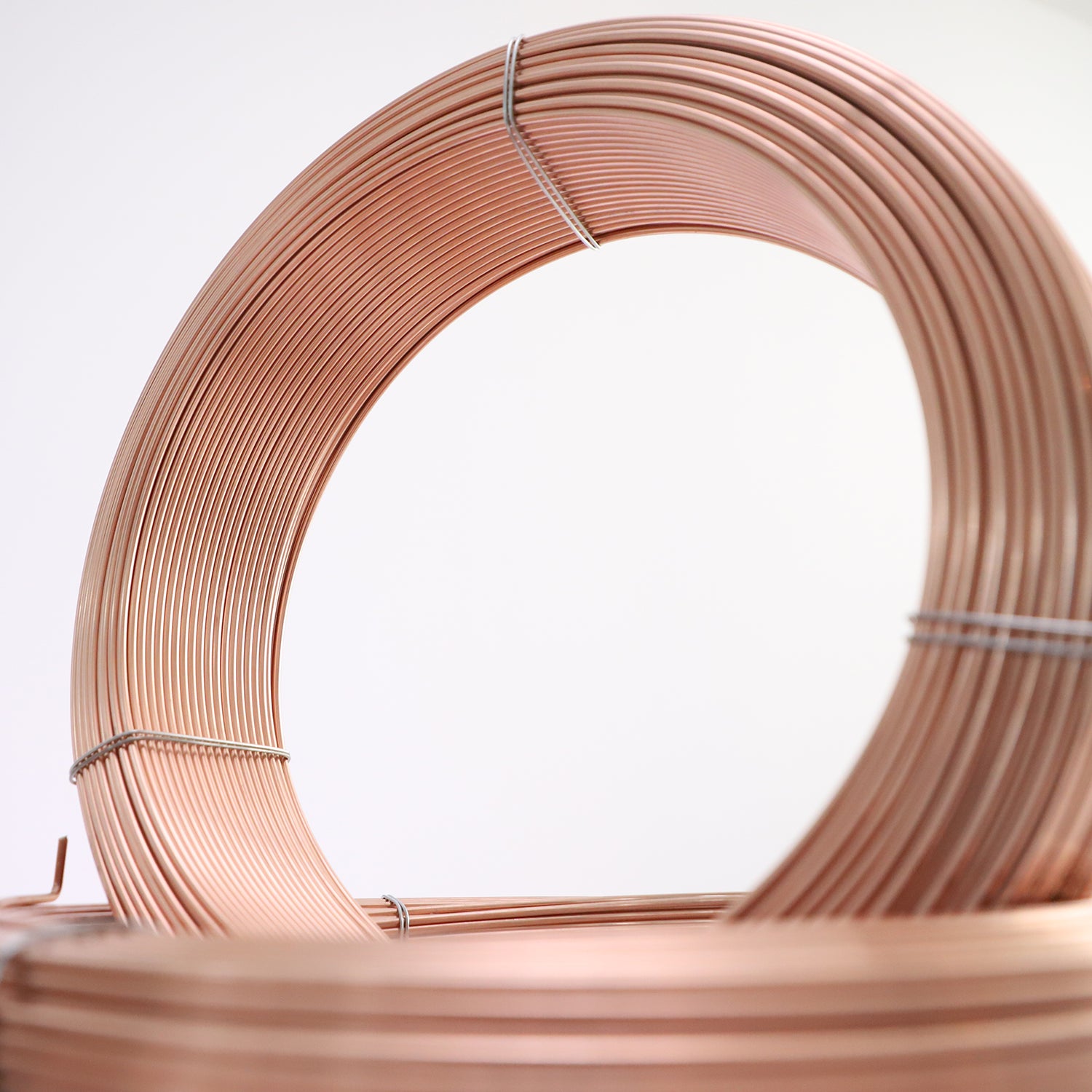

THM-43

THM-43

AWS A5.17 EL12

GB/ T5293 SU08A

Applications:

It is suitable for the welding of Rm 430MPa level carbon steel structure, such as SA-36/Gr.D, and so on.

Characteristic:

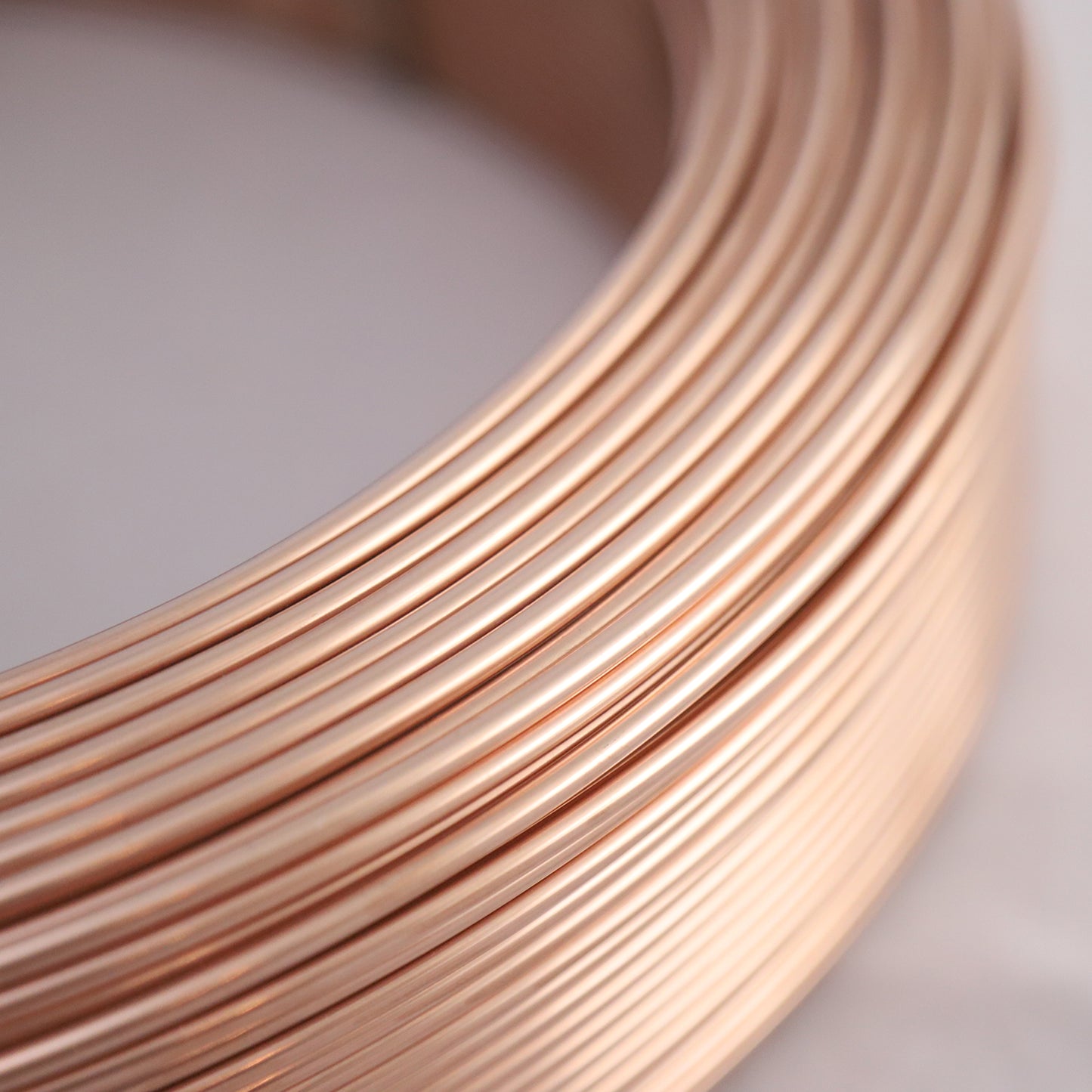

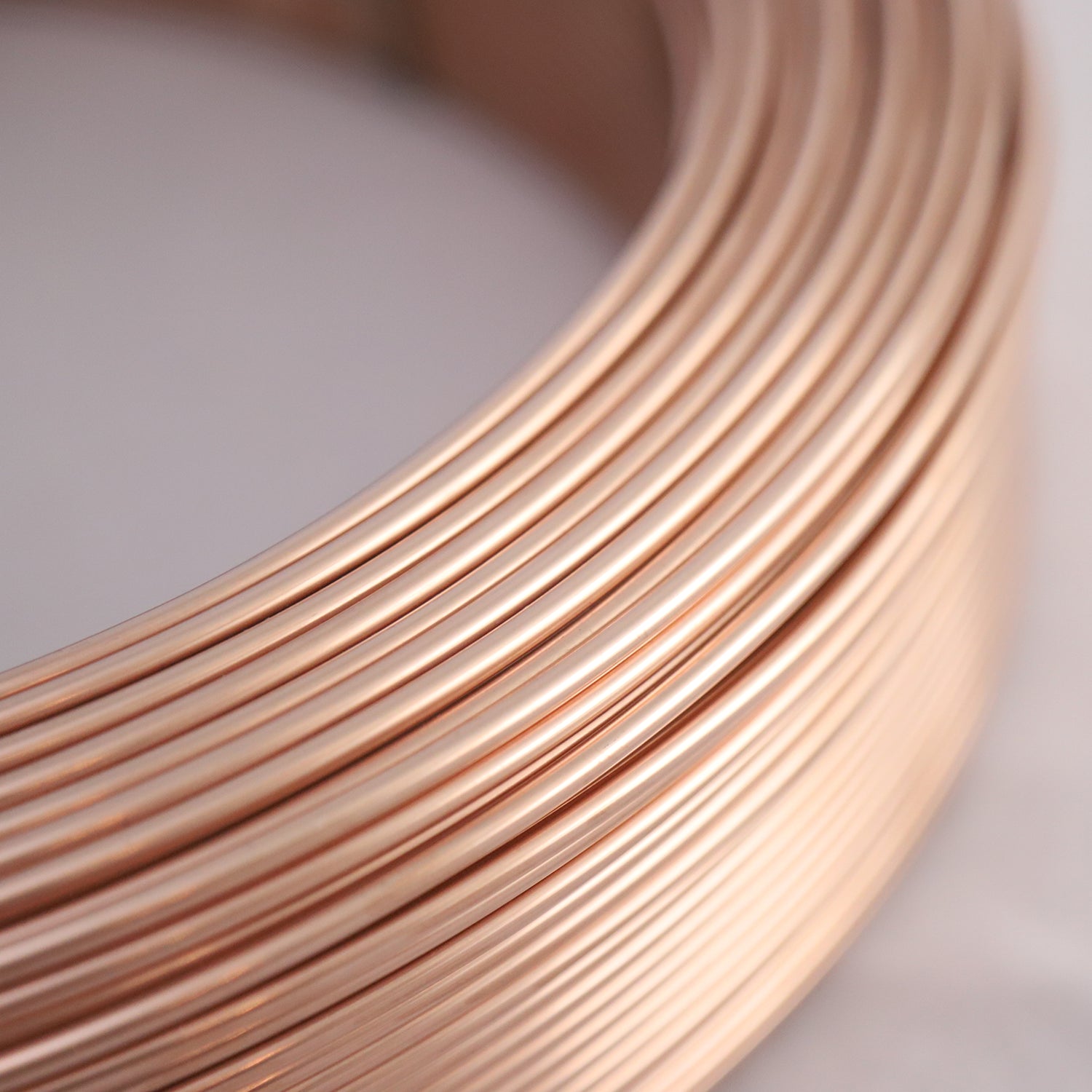

THM-43 is copper coated solid wire, and it can be used in automatic submerged arc welding with welding flux. The weld metal has excellent mechanical properties.

Attention:

1. The rust, oil, water and other impurities of the weld area must be removed before welding.

2. The mechanical properties of all weld metal be decided by heat input, normally the small heat input will better than larger one.

Chemical Composition of Wire: (Wt. %)

|

Item |

C |

Mn |

Si |

S |

P |

Cr |

Ni |

Cu |

|

Requirements |

≤0.10 |

0.40-0.65 |

≤0.03 |

≤0.030 |

≤0.030 |

≤0.20 |

≤0.30 |

≤0.35 |

|

Typical Results |

0.07 |

0.48 |

0.01 |

0.013 |

0.015 |

0.01 |

0.02 |

0.10 |

Mechanical Properties of All Weld Metal

(TH.SJ301/THM-43):

|

Items |

Rm/MPa |

Rel/Rp0.2 /MPa |

A% |

KV2 (-20℃) /J |

|

Requirement |

430-600 |

≥330 |

≥20 |

≥27 |

|

Typical Results |

460 |

375 |

28 |

80 |

Normal Diameter of Wire:

|

Size(mm) |

2.0 |

2.5 |

3.2 |

4.0 |

5.0 |

Classification of Society Certification:

|

Ship inspection agency |

CCS |

|

Level of recognition |

3TM |

Out of stock

Couldn't load pickup availability

Share