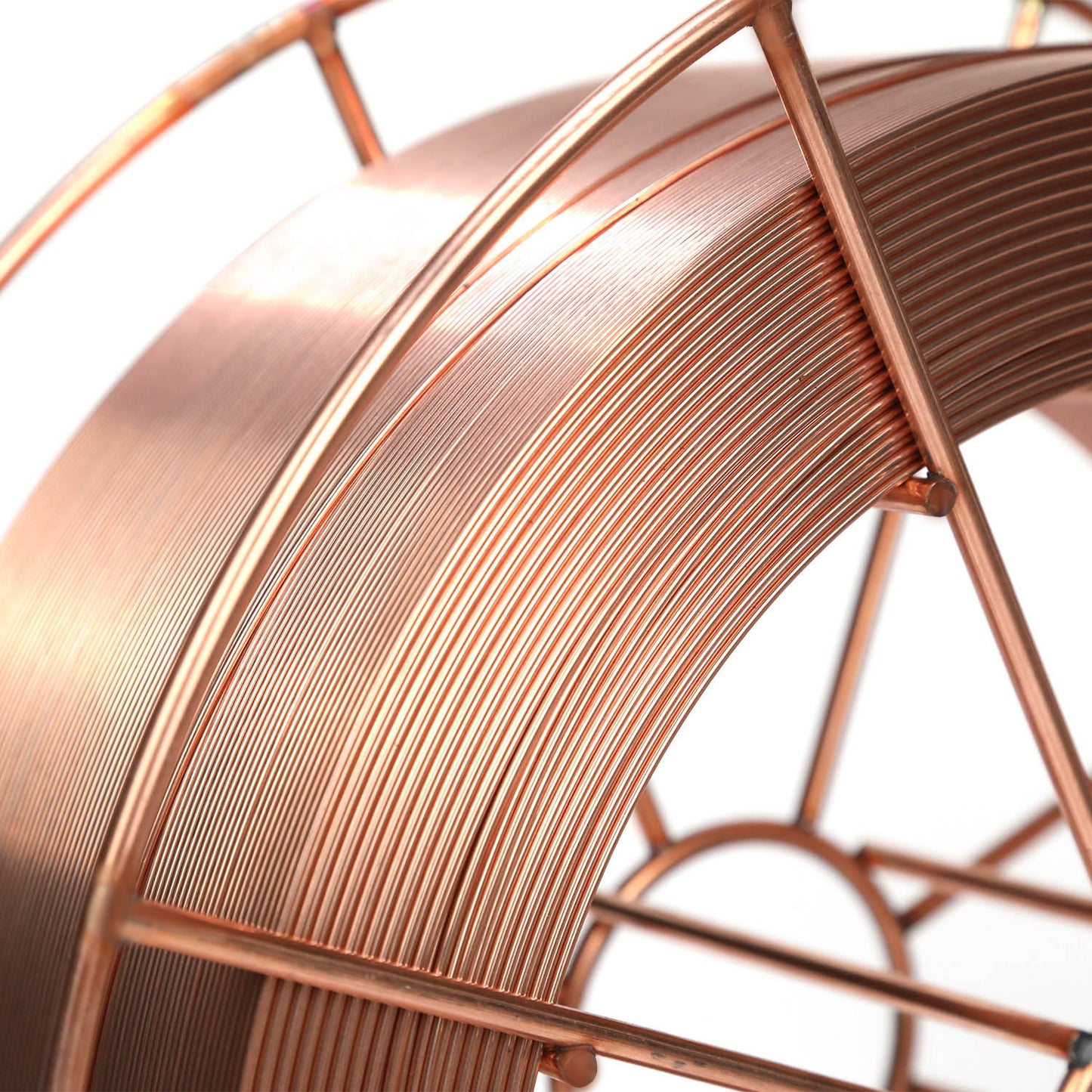

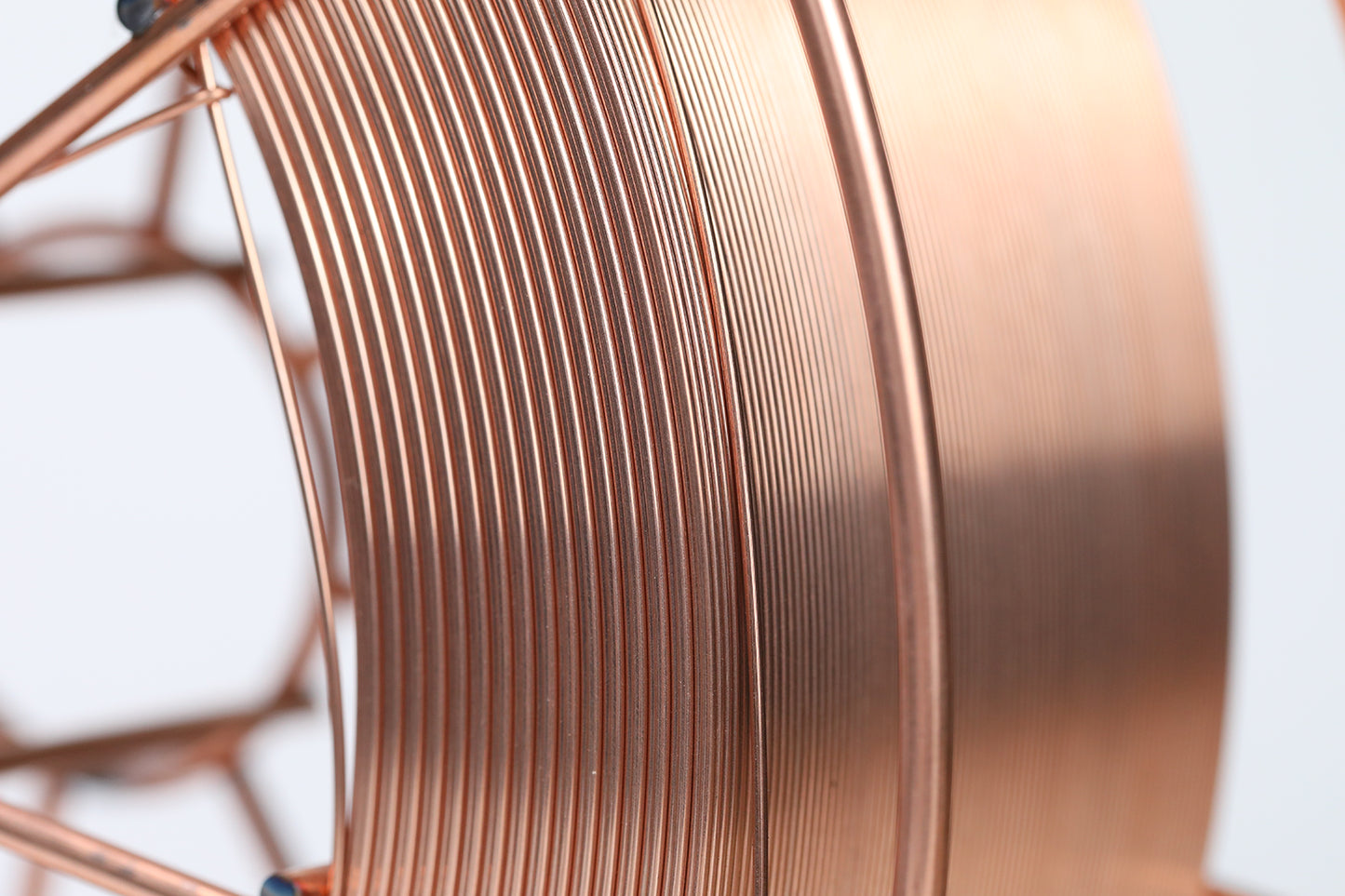

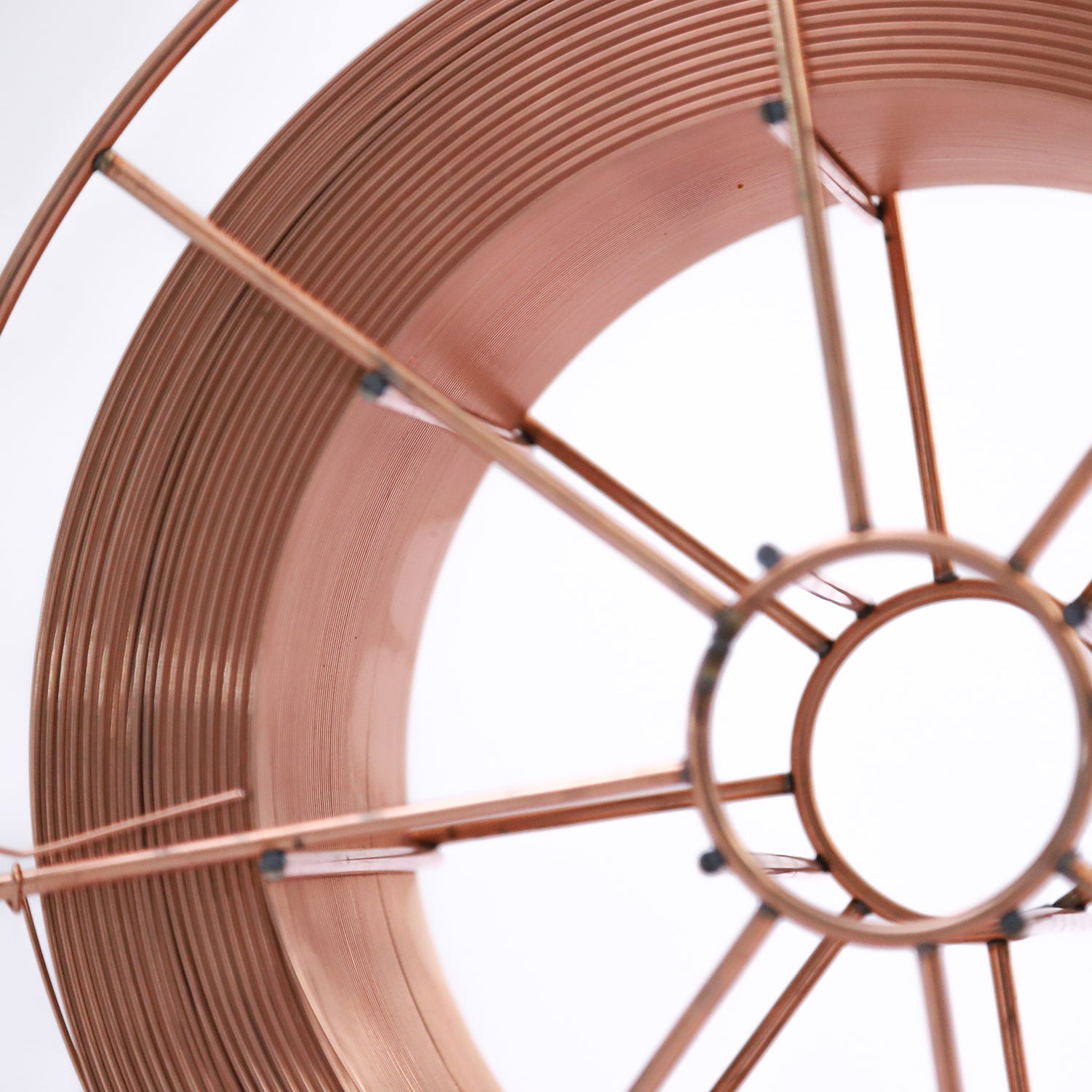

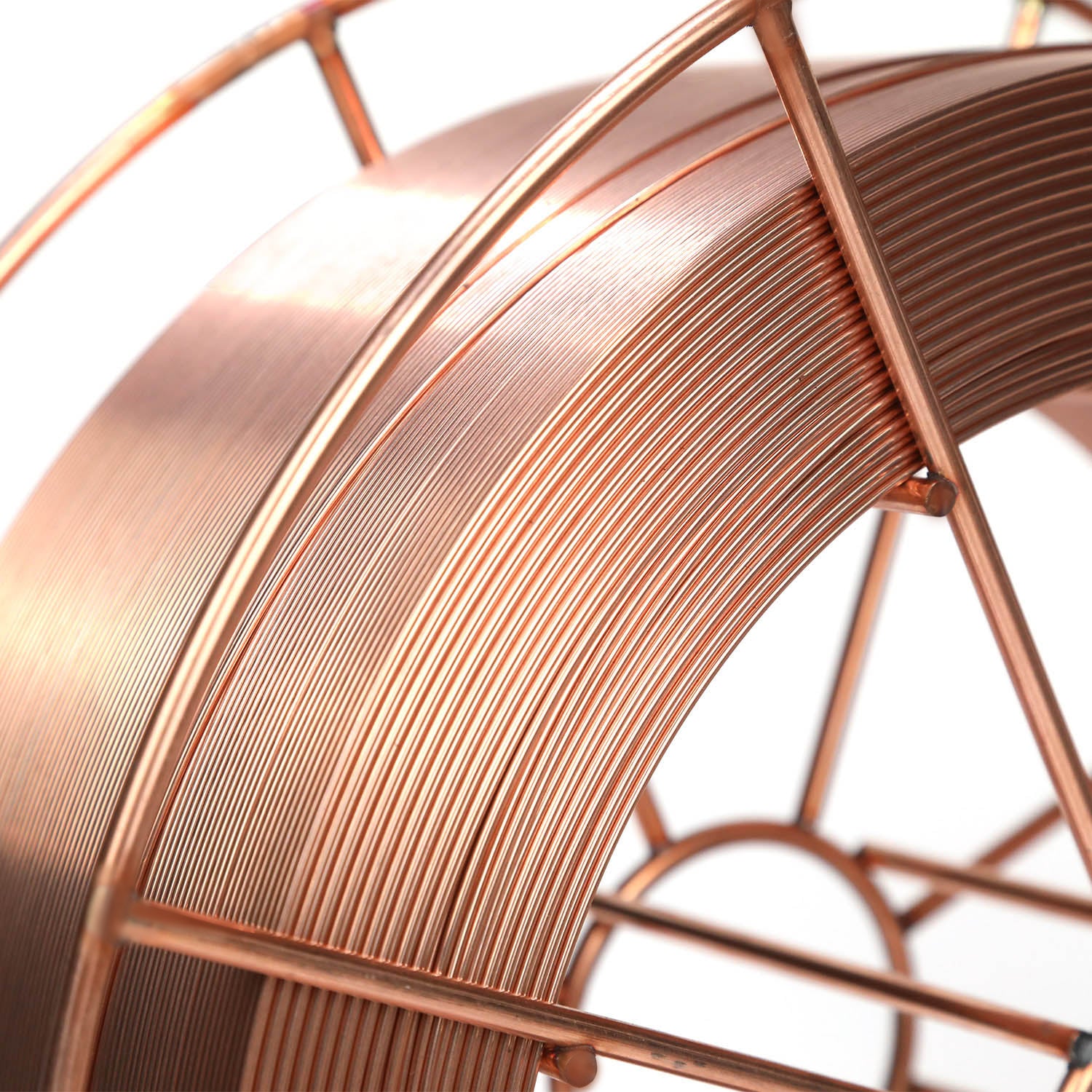

SG3

SG3

AWS A5.18 ER70S-6

ISO 14341-A-G38 3C1 4Si1

G42 4M21 4Si1

GB/T 8110 G49A3UC1S6

G49A4UM21S6

Applications:

It can be used in the welding of carbon steel and low alloy steel in the corresponding strength grade, which can be used in engineering machinery, shipbuilding, vehicle manufacturing, petrochemical and other industries, especially in the locomotive and rolling stock manufacturing industry.

Characteristics:

Wire of THQ-50CG4 is Rm 500MPa level carbon steel wire with shield gas of CO2 or M21. The welding spatter is small, and it has beautiful shape, high cladding efficiency. It can be used for all position.

Attention:

1. The rust, oil, water and other impurities of the weld area must be removed before welding.

2. The mechanical properties of all weld metal be decided by heat input, normally the small heat input will better than larger one.

Chemical Composition of Wire: (Wt. %)

|

Items |

C |

Mn |

Si |

S |

P |

Ni |

|

Requirements |

0.06-0.14 |

1.60-1.85 |

0.80-1.15 |

≤0.025 |

≤0.025 |

≤0.15 |

|

Items |

Cr |

Mo |

V |

Cu |

Al |

Ti+Zr |

|

Requirements |

≤0.15 |

≤0.15 |

≤0.03 |

≤0.35 |

≤0.02 |

≤0.15 |

Mechanical Properties of All Weld Metal:

|

Items |

Shield gas |

Rm/MPa |

Rel/Rp0.2 /MPa |

A/% |

KV2 /J |

|

Requirements |

C1 |

520-600 |

≥420 |

≥22 |

≥47(-30℃) |

|

Typical Results |

C1 |

560 |

440 |

30 |

58 |

|

Requirements |

M21 |

530-640 |

≥420 |

≥22 |

≥47(-40℃) |

|

Typical Results |

M21 |

580 |

483 |

28 |

88 |

X-ray Radiographic Inspection:

Level Ⅱ

Typical Operating Procedures: (DC +)

|

Diameter(mm) |

0.8 |

1.0 |

1.2 |

1.6 |

|

Current(A) |

50-180 |

70-230 |

80-350 |

120-500 |

EU Certification:

|

Certification Authority |

CPD-CE |

DB-AG |

VD-TÜV |

|

Grade |

ISO14341-A-G38 3 C1 4Si1/G42 4M21 4Si1 |

||

100000 in stock

Couldn't load pickup availability

Share