ER110S-G Welding Wire | High-Strength Low-Alloy Solid Wire

ER110S-G Welding Wire | High-Strength Low-Alloy Solid Wire

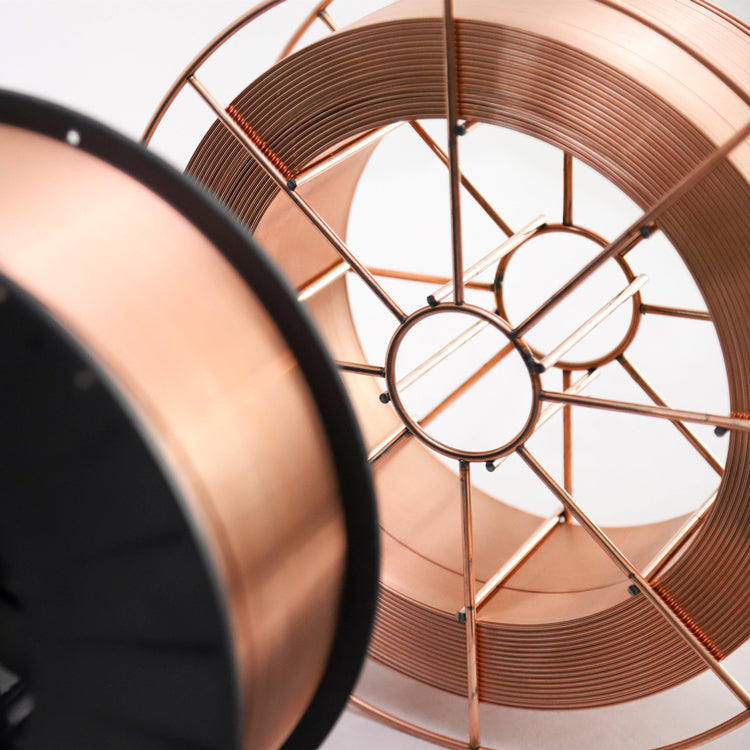

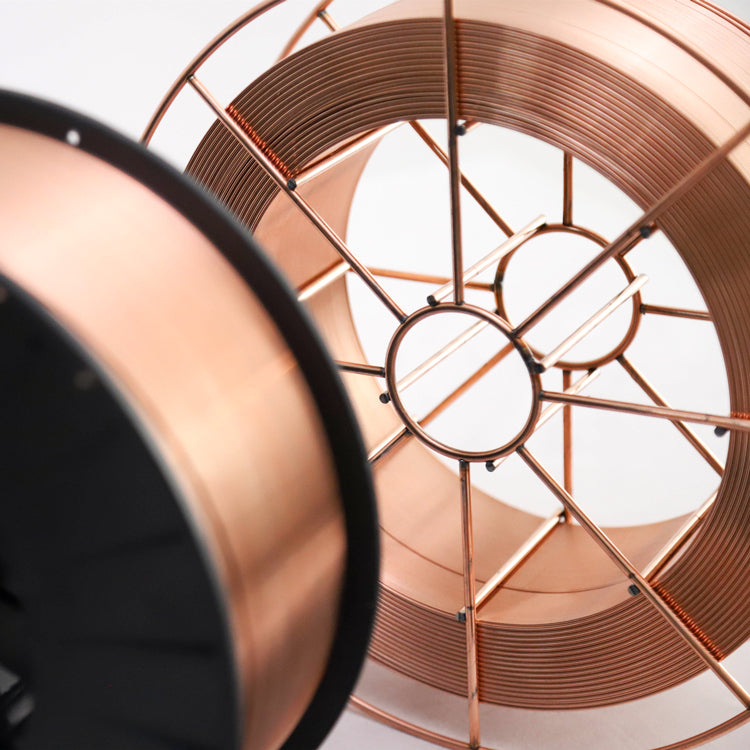

ER110S-G Welding Wire – High Strength Low Alloy Solid Wire

Introducing our high-performance welding wire ER110S-G, designed for welding of fine-grained, quenched and tempered high-strength steels. This low-alloy solid wire delivers excellent weld metal mechanical properties: tensile strength up to ~770-960 MPa depending on grade and process.

Applications

- Suitable for high-strength structural steel welds in pressure vessels, construction machinery, cranes, lifting equipment, pipelines and heavy engineering.

- Ideal when high yield strength, impact toughness (especially at sub-zero temperatures) and minimal rework are required.

Key Features

- Low-alloy composition with elements such as Ni, Cr, Mo for superior weld metal toughness.

- Stable arc performance under GMAW conditions (shielding gas Ar+20% CO₂ or similar mixtures).

- High tensile strength weld deposit (≥ 800 MPa typical) with good elongation and impact energy.

- Low spatter, good bead appearance and all-position capability for productivity.

Specifications (example values — please confirm for your version)

| Parameter | Typical Value |

|---|---|

| Standard | AWS A5.28 ER110S-G |

| Tensile strength (Rm) | ≥ 790 MPa |

| Yield strength (Rp0.2) | ≥690 MPa |

| Elongation (A) | ≥ 17% |

| Impact toughness | Excellent at -40 °C (example: 84 J) |

| Shielding gas | Ar + 20% CO₂, 15-25 L/min typical |

| Available diameters | 0.8 mm / 1.0 mm / 1.2 mm / 1.6 mm (as example) |

| Packaging | Spool 15/20kg, box/carton according to order |

| Ship Inspection Agency | ABS |

Welding Recommendations

- Use clean base metal: remove oil, rust, moisture, dust etc.

- Keep welding extension length 15-25 mm typical; maintain recommended gas flow.

- Monitor current range appropriate to diameter and position (see technical datasheet).

- Store welding wire in dry conditions to maintain quality.

Why Choose Bridge Brand’s ER110S-G?

As a trusted manufacturer with full certifications (ISO 9001, ISO 14001, ISO 45001, ISO 50001, CNAS, AEO …) and classification society approvals (ABS, BV, DNV, LR, etc.), Bridge Welding (your company) ensures consistent product quality, traceability and worldwide export capability.

We offer global logistics, customized packaging and technical support for demanding welding applications.

Couldn't load pickup availability

Share