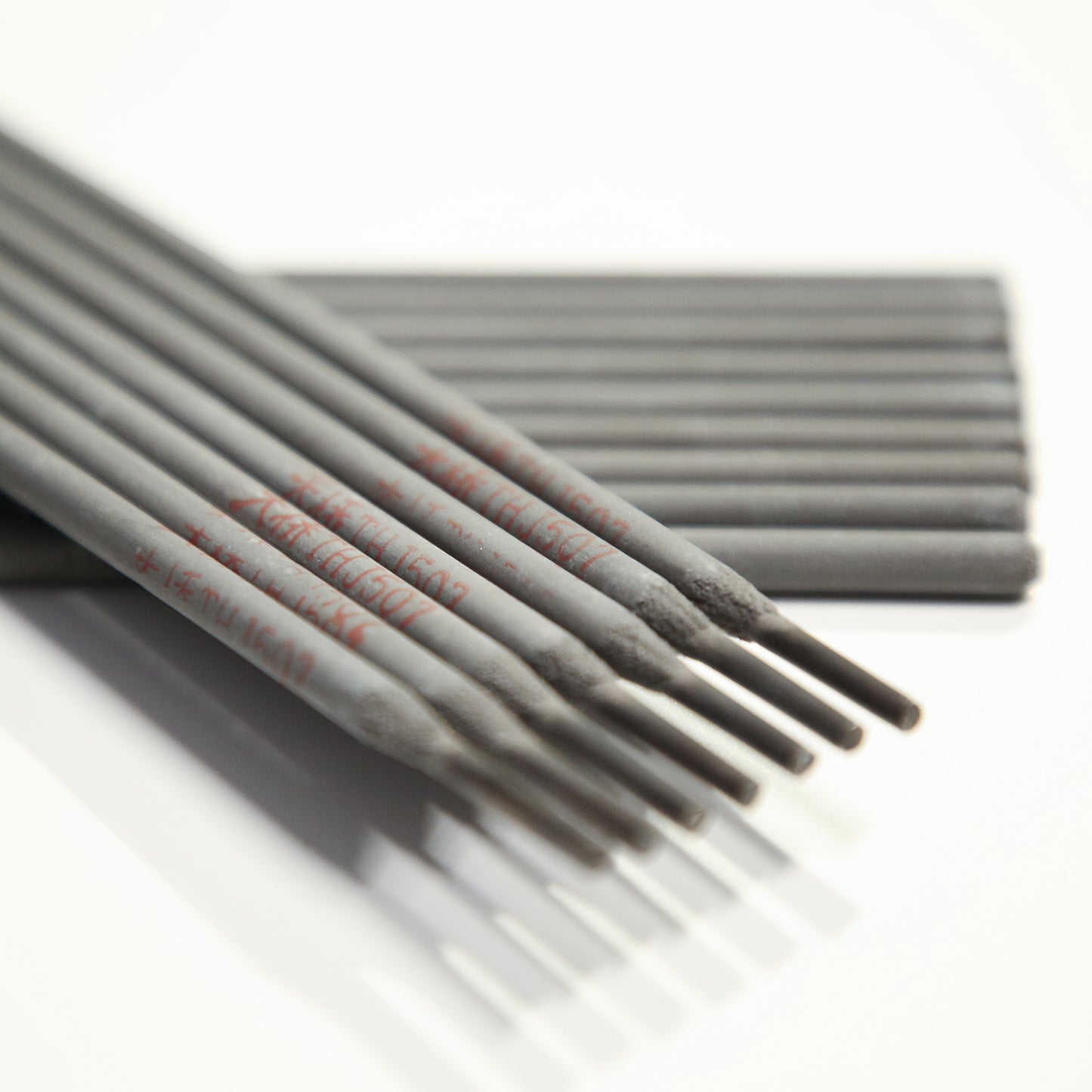

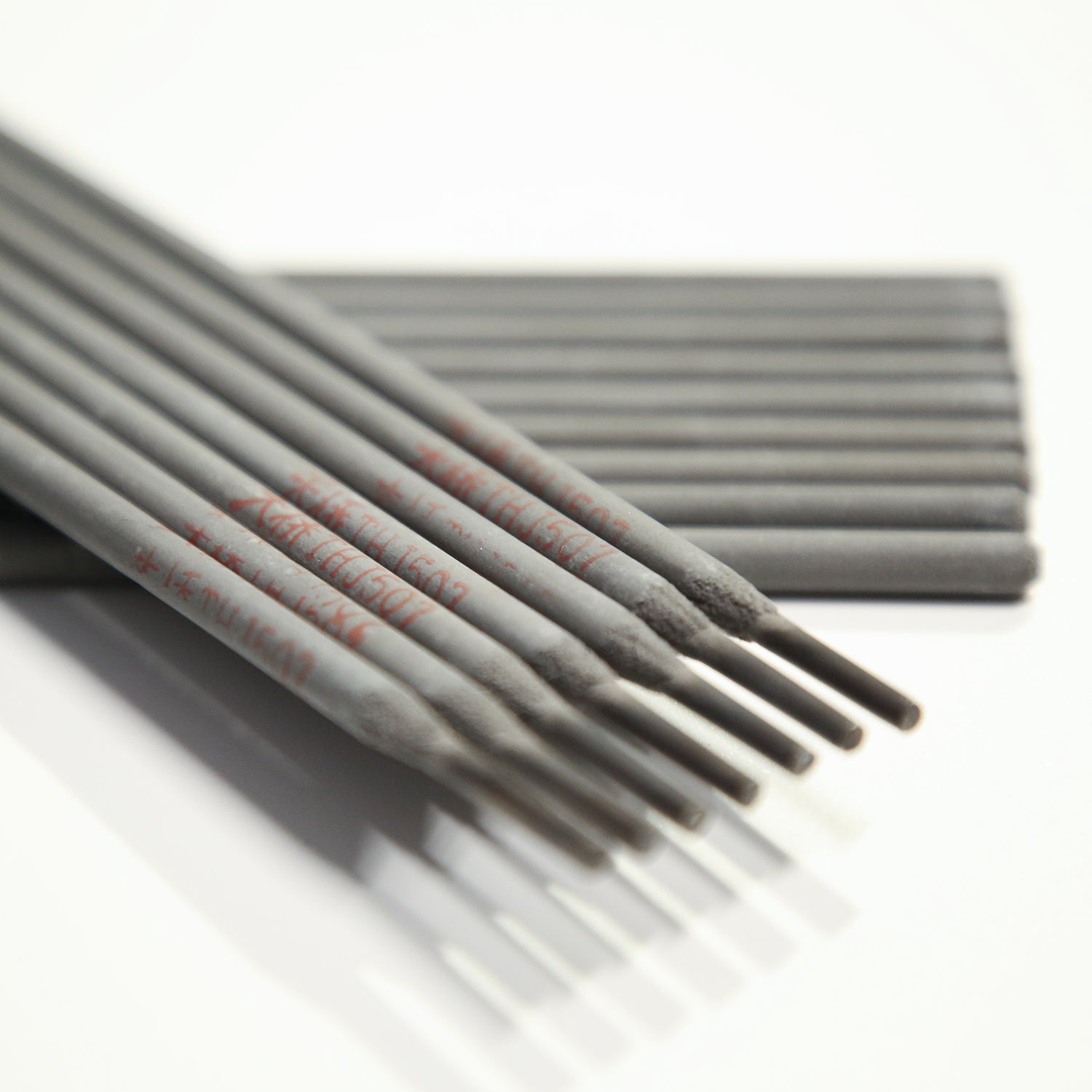

E7015 Welding Rod | Basic-sodium Type Electrode with Low Hydrogen

E7015 Welding Rod | Basic-sodium Type Electrode with Low Hydrogen

AWS A5.1 E7015

ISO 2560-A-E42 3 B 22 H5

GB/T 5117 E5015

Applications:

It is suitable for the welding of carbon steel and low alloy steel structure, such as Gr.50 etc.

Characteristics:

THJ507 is basic-sodium type electrode with low hydrogen. Can be weld for all-position with DC+ only. It have excellent welding performance as good arc stiffness, little spatter, easy slag removal etc., and perfect mechanical properties of deposited metal.

Attention:

1. The electrode must be re-dry by 350℃-380℃ for 1 hour before welding.

2. The rust, oil, water and other impurities of the weld area must be removed before welding.

Chemical Composition of All Weld Metal:(Wt. %)

|

Items |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

V |

|

Require-ments |

≤0.10 |

0.85-1.40 |

≤0.65 |

≤0.030 |

≤0.035 |

≤0.30 |

≤0.20 |

≤0.30 |

≤0.08 |

|

Typical Results |

0.07 |

1.00 |

0.32 |

0.012 |

0.017 |

0.030 |

0.035 |

0.005 |

0.004 |

Mechanical Properties of All Weld Metal:

|

Items |

Rm/MPa |

Rel/Rp0.2 /MPa |

A/% |

KV2 (-30℃) /J |

|

Requirements |

500-640 |

≥420 |

≥22 |

≥80 |

|

Typical Results |

580 |

490 |

30 |

180 |

X-ray Radiographic Inspection:

LevelⅠ

Typical Operating Procedures:(DC+)

|

Diameter (mm) |

2.0 |

2.5 |

3.2 |

4.0 |

5.0 |

5.8 |

|

Length (mm) |

300 |

300 |

350 |

400 |

400 |

400 |

|

Current (A) |

40-70 |

60-90 |

90-130 |

140-180 |

180-230 |

20-280 |

Classification of Society Certification:

|

Ship Inspection Agency |

ABS |

BV |

CCS |

DNV.GL |

RS |

|

Recognition Level |

3YH10 |

3YHH |

3YH10 |

3YH10 |

3YH10 |

|

Ship Inspection Agency |

LR |

NK |

KR |

RINA |

--- |

|

Recognition Level |

3YmH15 |

KMW53H10 |

3YH10 |

3YH10 |

--- |

The European Union Certification:

|

Certification Authority |

CPD - CE certification of steel structure |

|

Grade |

ISO 2560-A-E42 3 B22H5 |

100000 in stock

Couldn't load pickup availability

Share