E308L-16

E308L-16

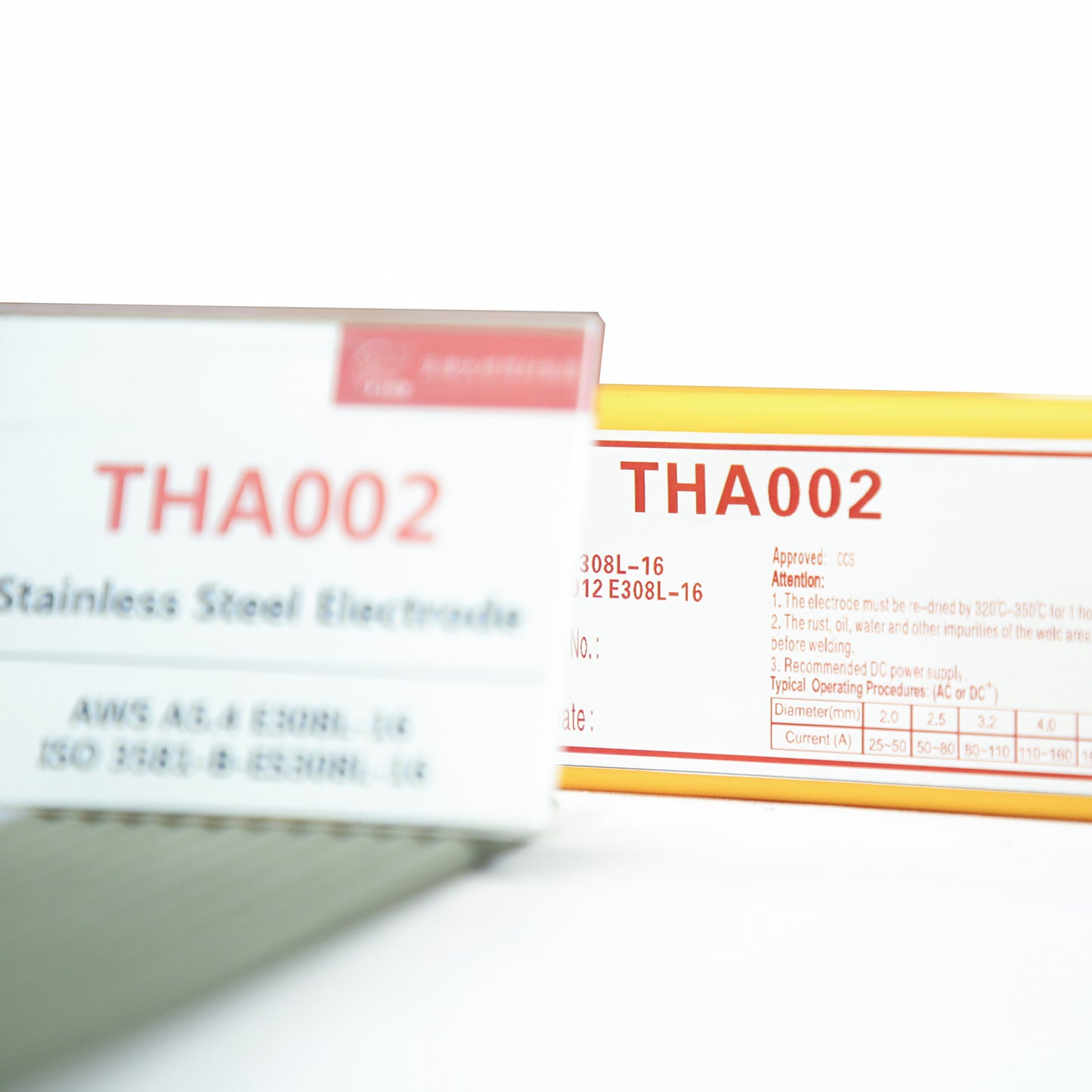

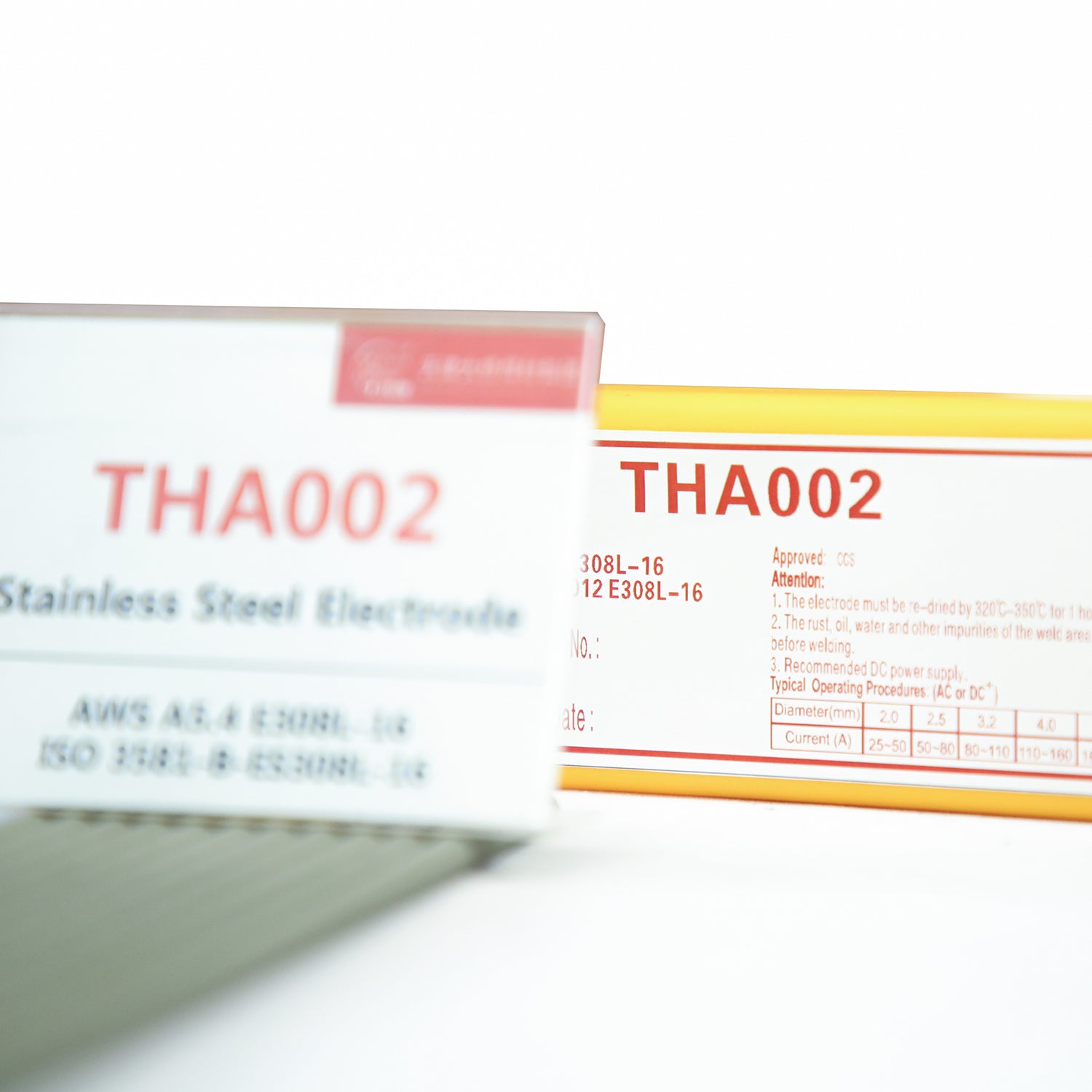

AWS A5.4 E308L-16

ISO 3581-B-ES308L-16

GB/T 983 E308L-16

Applications:

For welding of ultra-low carbon’s SUS304L stainless steel, also can be used for SUS321 and other corrosion resistant stainless steel structure.

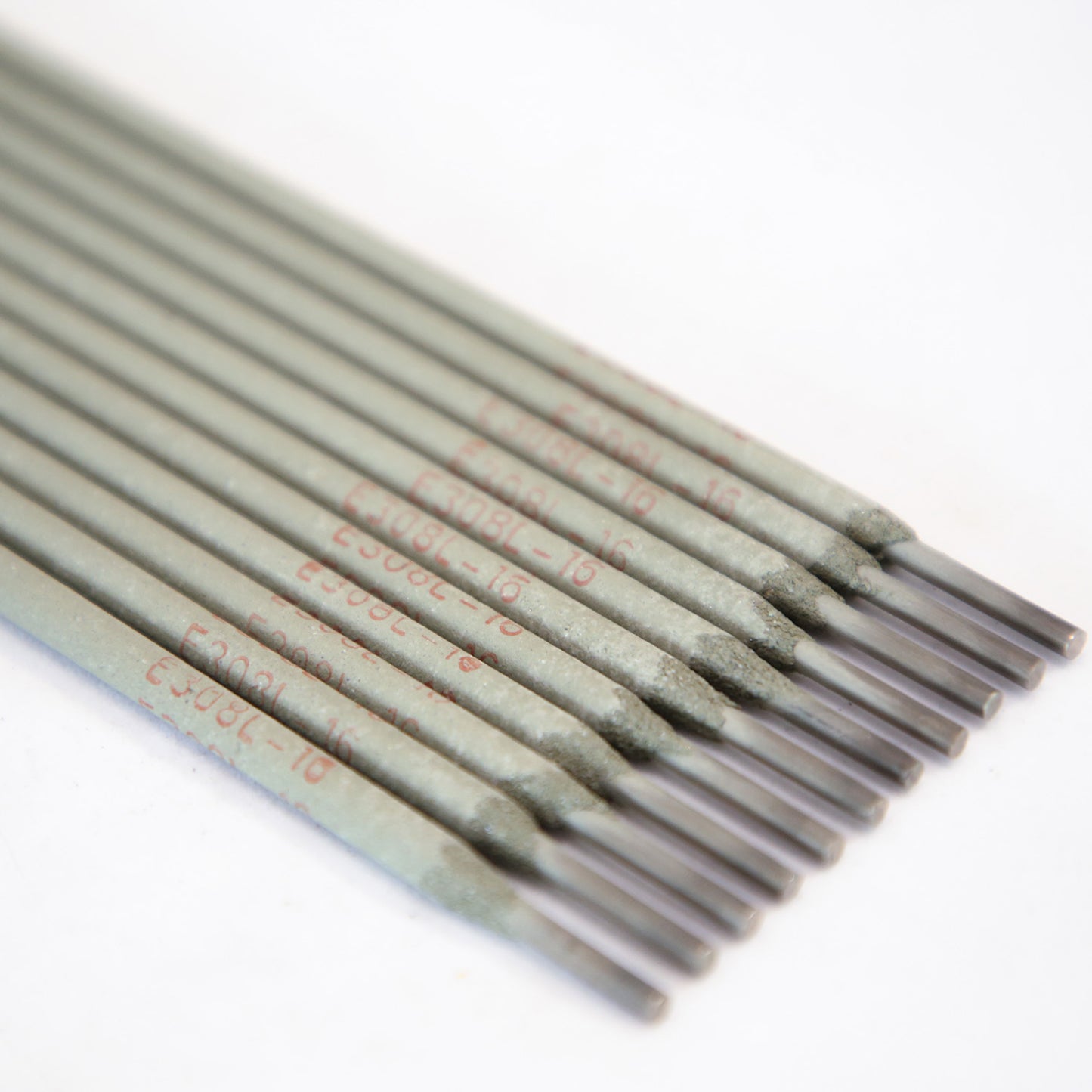

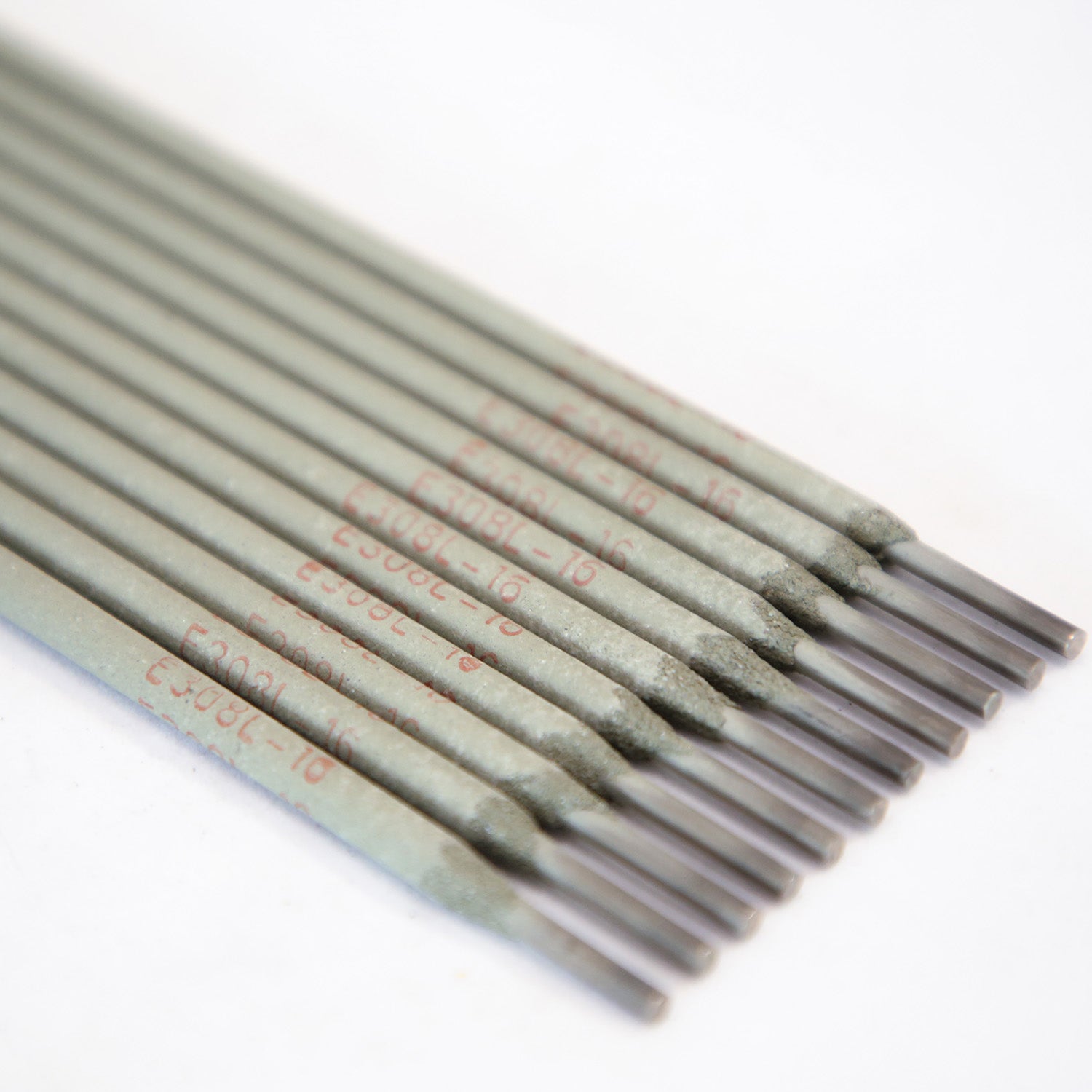

Characteristics:

THA002 is rutile type stainless steel electrode with ultra-low carbon. Can be weld for all-position with AC or DC. It have excellent welding performance as good arc stiffness, little spatter, easy slag removal etc., and perfect intercrystalline corrosion resistance of deposited metal.

Attention:

1. The electrode must be re-dry by 320℃-350℃ for 1 hour before welding.

2. The rust, oil, water and other impurities of the weld area must be removed before welding.

3. DC+ is better than AC, lower heat input is suggested, the temperature of preheat and interpass keep under 150℃.

Chemical Composition of All Weld Metal:(Wt. %)

|

Items |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

Cu |

|

Require-ments |

≤0.04 |

0.5-2.5 |

≤1.00 |

≤0.03 |

≤0.04 |

9.0-12.0 |

18.0-21.0 |

≤0.75 |

≤0.75 |

|

Typical Results |

0.029 |

0.94 |

0.73 |

0.010 |

0.028 |

9.60 |

19.60 |

0.08 |

0.10 |

Mechanical Properties of All Weld Metal:

|

Items |

Rm/MPa |

A/% |

|

Requirements |

≥510 |

≥30 |

|

Typical Results |

578 |

41 |

Typical Operating Procedures:(AC or DC+)

|

Diameter (mm) |

2.0 |

2.5 |

3.2 |

4.0 |

5.0 |

|

Length (mm) |

300 |

300 |

350 |

400 |

400 |

|

Current (A) |

25-50 |

50-80 |

80-110 |

110-160 |

160-200 |

Classification of Society Certification:

|

Ship Inspection Agency |

CCS |

|

Recognition Level |

304L |

100000 in stock

Couldn't load pickup availability

Share